After 24 months of intensive R&D work by FSES and Shenzhen Micronic Technology Co. Ltd., the new 8 probe Innovation Test System (driven by the OctaStar Software) made its debut at HKPCA in Shenzhen.

Innovation Test System

FSES Engineer Seth Sheades recently returned from another extended visit to Micronic facilities in Hong Kong and Shenzhen. During this visit, his first to Mainland China since 2019, he worked intensively with our partners from Shenzhen Micronic Technology Co. Ltd. addressing points with the ProbeStar and OctaStar software packages. This was another fruitful visit advancing the performance of all Micronic Test Systems.

From May 24-26 he also visited the HKPCA Show in Shenzhen where he met with customers, partners and even some old colleagues.

Four Stars Engineering Systems is happy to introduce new team member Dr. Xuhui Li. Dr. Li joined FSES at the beginning of 2023 and has been working diligently to integrate himself into several hardware projects under the direction of Bernhard Driller with the target of overtaking several of the projects moving forward.

Dr. Li has over 30 years of experience in the field of Electrical Engineering and will be a valuable addition to the team as he continues development of both existing and new products.

FSES Engineer Seth Sheades recently returned from a three month visit to the Micronic office in Hong Kong. He spent this time there with Mak Waitung and Tony Wong performing an intensive OctaStar Software Integration in the Innovation System and providing real time training and evaluation of the complete system.

The trip was very successful and all anticipate great success in the future!

FSES announces it’s latest software, OctaStar. This new application is used to drive the next generation Innovation Test System built by Shenzhen Micronic Technology Co., Ltd.

See the Product Page OctaStar Software for more information.

FSES announces the release of the System Control Board SCBMX. This new hardware module is used to drive the next generation Innovation Test System built by Shenzhen Micronic Technology Co., Ltd.

See the Product Page SCBMX for more information.

Earlier in June Four Stars Engineering Systems reached the 1000 ProbeStar license sold plateau. Considering the close relationship with our partners at Shenzhen Micronic Technology Co., Ltd and the percentage of license distribution into Greater China, it is fitting that this has occurred 8 years and 8 months after the sale of the first ProbeStar license.

Thank you to our partners with whom we share our success!

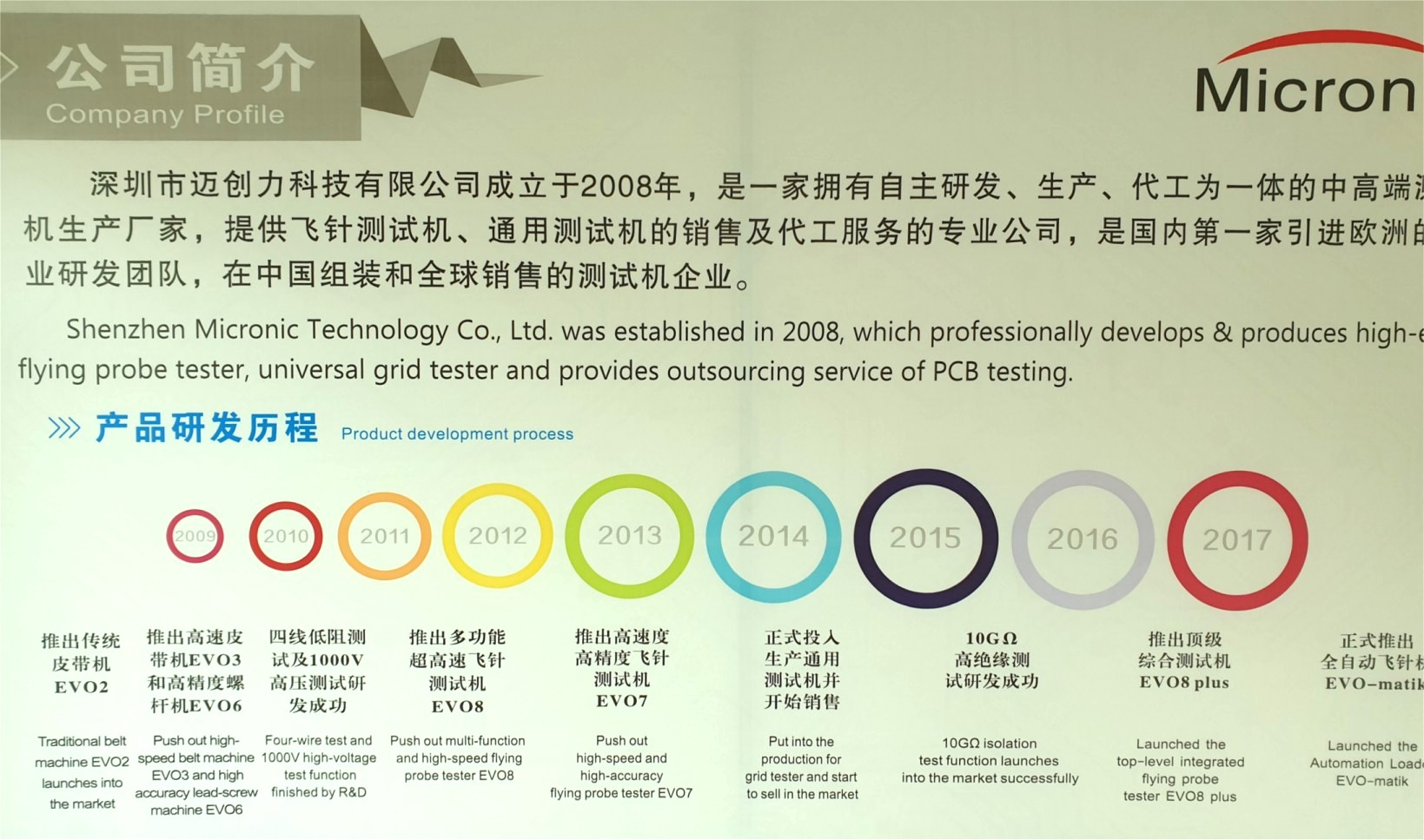

Picture above shows a diagram printed on the wall in Micronic’s entrance hall doumenting the large technological steps Micronic and Four Stars Engineering have made together since establishment of the companies.

Influenced from the contents of the diagram, the milestones of the commen history were the subject of Bernhard’s speech during the annual lunch at Chinese New Year Celebration 2019/2020:

Two Side Automation redesign for larger panel sizes now available.

PCB maximum width is extended from 460mm to 500mm in Versin 2SW and 2SWX.

PCB maximum height is extended from 325mm to 350mm in version 2SW.

PCB maximum height is extended from 325mm to 450mm in version 2SWX.

More information here: roboStar-2S